|

| PCB - Simple 12V battery charger with automatic charging indicator |

This is a Smart Battery Charger, with fully automatic 12V battery charge indicator. It is an extremely simple charger that anyone with little experience can assemble.

The input voltage depends on the power supply you are using, 110Vac or 220Vac. The charging time depends on the power supply you are using and the type of battery you are charging.

To calculate the closest charging time, we can do a simple and objective quick calculation that does not take into account the variations of the resistance factors of the battery, the variations of the charger, the chemical depreciation factor of the battery and so on.

You may be interested in:

The calculation is quite simple. Let us take an example: you have a UPS 12 volt battery with 7 amps, your power supply is 3 amps.

So we know that the battery charge is "more or less" 7 Amps Hour, which means that to fully charge the battery, 7 constant amps are required. Since the power supply is 3 amps, we need to divide 7 amps by 3 amps of power supply.

To charge a battery without damaging it usually requires a current of 10% and a maximum of 20% of its current. For example:

If our battery is 7 amps, the most we need is a 1.4 amp charger, and normal charging consumption is 700 milliamps. This 10% is normally used in devices that are directly connected to the power, such as alarm systems, backup devices and others.

Let's do the calculations using the formula

- B = battery

- PS = power supply

- C = current

C = B / PS

C = 7/3 C = 2.33

Meaning:

Charge "C" lasts 2:33 hours

Two hours and thirty-three minutes to charge

If your PS is different, no problem, look at its supply current and put in the formula to see the approximate result.

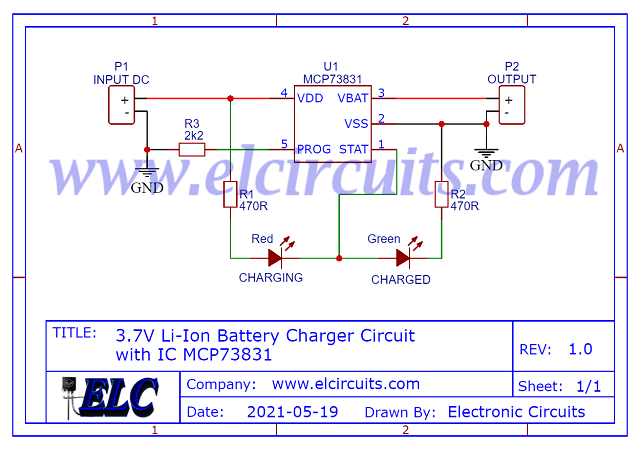

Figure 2 shows the complete electrical schematic of the small circuit.

|

| Fig. 2 - Electronic Schematic Simple 12V Automatic Battery Charger |

It is important that the power supply delivers 20% more than the battery voltage, e.g. if your battery is 12 V, the power supply must be 14,4 V. You can vary a little, e.g. 13.2 V, "which is 10% of the battery voltage", but you cannot use a 12 V power supply to charge a 12 V battery as there will be no potential difference.

Here is how to use the charger:

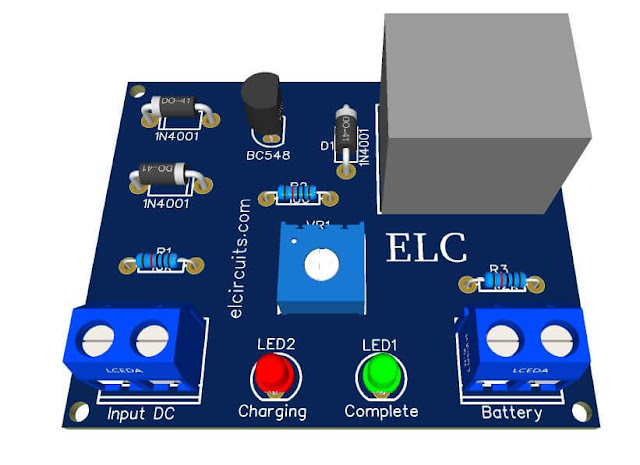

When all the assembly is done, carefully check for wrong parts, reverse polarity diodes and shorts in the terminals after checking everything.

Connect the positive terminal of the power supply to the input of the +Vcc circuit and the negative terminal of the power supply to the ground circuit of the charger.

With the potentiometer or trimpot you can regulate the output voltage of the charger, for example you have a 12V battery, normally 12V batteries UPS are charged at 13.2V at 14.4 volts.

Then use a multimeter on the DC volt scale, "it depends on the multimeter", on the output of the charger and set the voltage to the most desired, ie the maximum voltage for it to fire and the green LED will light up.

You can now use your new charger, insert the battery and let it charge until the charger reaches the voltage you set, "limit voltage", it will trigger the relay and turn on the green LED, indicating that the battery has been charged.

A good tip: If you have a spare 12v buzzer, or if you really want to add an audible indicator to your circuit, you can connect these buzzers, which you can easily find in electronics stores and are cheap, to the output where the green LED is lit, which is the full charge indicator, and you can turn on the positive buzzer on the relay output and the negative buzzer directly on the output.

Material List:

- Q1..................... General purpose NPN transistor, C1815, BC548 etc.

- D1, D2, D3 ...... Diodes 1N4001.

- R1 ..................... Resistor 1/8W 10K (Brown, Black, Orange)

- R2 ..................... Resistor 1/8W 100 Ohms (Brown, Black, Brown)

- R3 ..................... Resistor 1/8W 1K2 (Brown, Red, Red)

- VR1 ................. 10K Trimmpot or Potentiometer

- P1, P2 ............... KF301 2 Pin 5.08mm Pitch Plug-in Screw Terminal Block Connector

- RL1 ................... Relay 12V 10A, 5 pins

- LED1, LED2 .... 3mm LEDs, one Red and one Green

- Others ............... Printed circuit board, soldering iron, tin, wire, etc.

Download:

If you have any questions, suggestions or corrections, please leave them in the comments and we will answer them soon.

Subscribe to our blog!!! Click here - elcircuits.com!!!

My Best Regards!!!