100W Audio Power Amplifier with TIP142 and TIP147 and PCB

Have you ever looked at a complex audio project and felt like the barrier to entry was just too high? For many electronics hobbyists, the jump to high-power amplification is often stalled by overly complicated circuits and tedious calibration requirements. Today, we’re stripping all of that away to focus on what really matters: raw power and reliable performance.

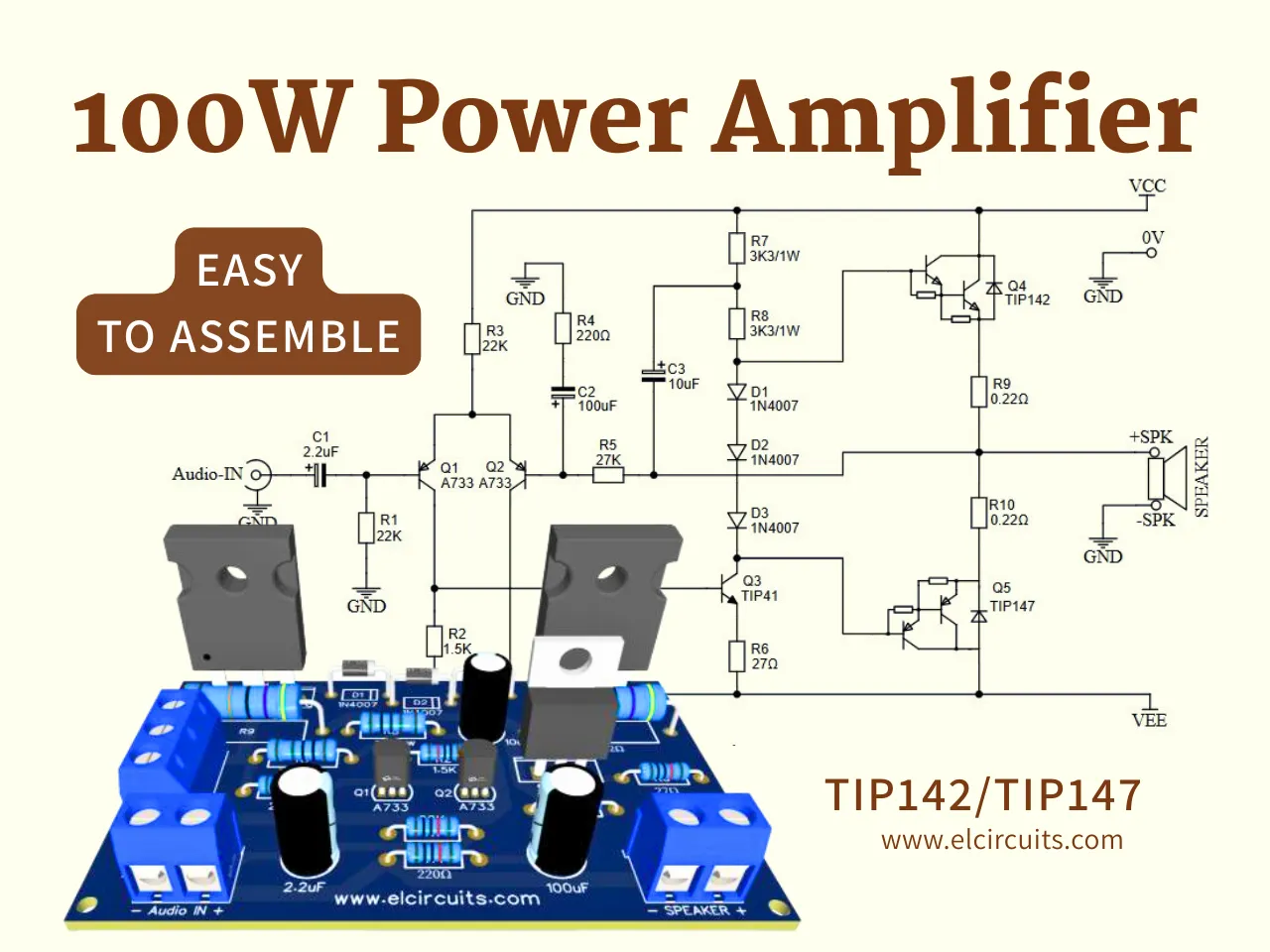

In the lab, we see plenty of designs that look good on paper but are a headache to build. This configuration is different. It’s a straightforward Class AB design that strikes the perfect balance between a minimal component count and heavy-duty output. If you have basic soldering skills and know your way around a breadboard, you can pull this off. By the end of this guide, you’ll have a rugged 100W RMS power stage capable of driving demanding speakers, powered by the legendary TIP142 and TIP147 Darlington transistors.

⏯️ Understanding the Circuit Architecture

Bottom Line Up Front: This amplifier utilizes a Class AB output stage with a complementary Darlington pair (TIP142/TIP147) driven by a differential input stage, offering efficiency and simplicity suitable for general-purpose high-power audio.

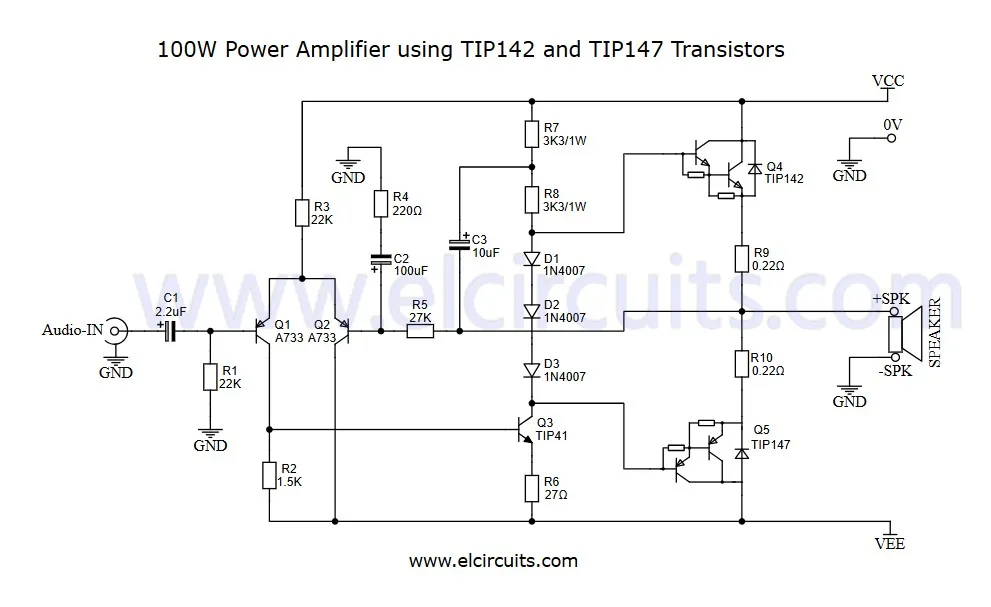

Before we start soldering, let's dissect the beast. This isn't just a bunch of parts thrown together; it is a carefully designed signal chain. The circuit is divided into three main stages: Input/Differential, Voltage Amplification/Driver, and Current Amplification/Output.

The Differential Input Stage (The Brain)

The input stage is formed by a differential pair consisting of transistors Q1 and Q2 (both PNP A733). Think of a differential pair as a balance scale. It compares two signals and amplifies only the difference.

Here is how it works in our circuit: Q1 receives the actual audio input signal (the music). Q2, however, receives the Feedback signal taken from the amplifier's output. This creates a closed loop.

Why is this critical? As a professor, I often tell my students: "An amplifier without feedback is like a car without a steering wheel." The feedback signal tells the input stage exactly what the output is doing. If there is any distortion or error in the output, the differential pair subtracts it from the input, instantly correcting the error. This mechanism gives the amplifier its stability and significantly reduces harmonic distortion.

The Driver Stage (The Muscle)

The second stage features the TIP41 transistor. In technical terms, this is the Voltage Amplification Stage (VAS). The signal coming from the differential pair is correct, but it's weak. It doesn't have enough "oomph" to drive the heavy output transistors.

The TIP41 acts as a booster. It takes the voltage from the differential pair and prepares a high-current signal to charge the bases of the final output transistors. Without this driver, your sound would be thin and quiet.

The Output Stage (The Powerhouse)

This is where the magic happens. We use a complementary pair of Darlington Transistors: the TIP142 (NPN) and TIP147 (PNP).

What is a Darlington Transistor? Imagine connecting two transistors face-to-face so their current gains multiply. A single transistor might have a gain of 100. A Darlington pair can have a gain of 10,000 or more. This means a tiny current from the TIP41 can control a massive current flow through the speakers. The TIP142 handles the positive "push" of the music waveform, while the TIP147 handles the negative "pull."

🔌 The Schematic Diagram

Now, let's look at the blueprint. In our bench tests, this configuration consistently delivered a little over 100W RMS into a standard load. The schematic diagram below is optimized for clarity. It uses few external components, which reduces the chance of assembly errors.

⚠️ A Critical Safety Note: We are dealing with high voltage here. When powered with the recommended transformer, the circuit rails sit at roughly +/- 50V DC. This means there is a potential difference of 100V across the circuit. Always double-check polarities. Never short the output while the amplifier is powered on, or you will instantly say goodbye to your output transistors.

⛔ The Role of Biasing Diodes

You might notice diodes D1, D2, and D3 in the schematic. These are not just protection devices; they are the "thermostat" of the amplifier. In a Class B amplifier, there is a tiny "dead zone" where the music signal crosses from positive to negative. Without proper biasing, the amplifier creates a "crossover distortion" that sounds harsh.

These diodes create a small voltage drop (about 2.1V total) that keeps the TIP142 and TIP147 slightly turned on even when there is no music. This smooths out the transition between the NPN and PNP transistors. Since diodes and transistors are made of similar silicon materials, as the output transistors heat up, these diodes track the temperature change, adjusting the bias automatically to prevent thermal runaway. Neat, right?

⚡ Power Supply Requirements

Bottom Line Up Front: You need a symmetric power supply of +/- 50V DC (derived from a 36V-0V-36V AC center-tapped transformer) capable of delivering at least 3 Amps to achieve the full 100W RMS output.

Great amplifiers need great lungs. The power supply is the lungs of your audio system. For this project, we recommend a Center-Tapped Transformer with a secondary rating of 36V - 0V - 36V AC.

Why 36V AC to get 50V DC? It's simple math. The DC voltage of a rectified AC signal is roughly the AC RMS value multiplied by 1.414 (the square root of 2).

- Calculation: 36V AC × 1.414 ≈ 50.9V DC (Under load, this settles comfortably around 50V).

- Current: Aim for 3 Amperes to ensure headroom for bass peaks.

- Filtering: Use high-capacity electrolytic capacitors (at least 4700uF per rail, 63V rating) on the power supply board to smooth out the ripples. Think of these as water towers keeping the pressure steady.

🧾 Component List

Here is the bill of materials. Quality matters. Don't use the cheapest resistors you can find; 1% tolerance metal film resistors are preferred for the input stage to ensure noise rejection, though 5% carbon film works for general testing.

Semiconductors

- Q1, Q2: A733 (or BC556, BC560) – PNP Transistor (High gain, low noise).

- Q3: TIP41C – NPN Transistor (Driver).

- Q4: TIP142 – NPN Darlington Power Transistor (Output Positive).

- Q5: TIP147 – PNP Darlington Power Transistor (Output Negative).

- D1, D2: 1N4007 – Rectifier Diode.

Resistors

- R1, R2: 22kΩ (Red, Red, Orange, Gold) – Feedback divider.

- R3: 1k5Ω (Brown, Green, Red, Gold) – Input resistor.

- R4: 220Ω (Red, Red, Brown, Gold) – Base protection for driver.

- R5: 27kΩ (Red, Violet, Orange, Gold) – Feedback resistor.

- R6: 27Ω (Red, Violet, Black, Gold) – Base current limiter.

- R7, R8: 3k3Ω (Orange, Orange, Red, Gold) – 1W Wattage! These stabilize the driver stage.

- R9, R10: 0.22Ω (Red, Red, Gold, Silver) – 3W Wattage! These are Emitter resistors. Do not omit them; they share the current load between the output transistors and prevent oscillation.

Capacitors

- C1: 2.2µF – 25V – Electrolytic (Input DC blocking).

- C2: 100µF – 63V – Electrolytic (Filtering for the driver).

- C3: 10µF – 63V – Electrolytic (Bootstrap capacitor - essential for high power swing).

Miscellaneous

- P1, P2: 5mm 2-Pin Terminal Connector.

- P3: 5mm 3-Pin Terminal Connector.

- PCB: Printed Circuit Board (Files below).

- Heatsink: Essential. A large aluminum heatsink with thermal paste for TIP142 and TIP147.

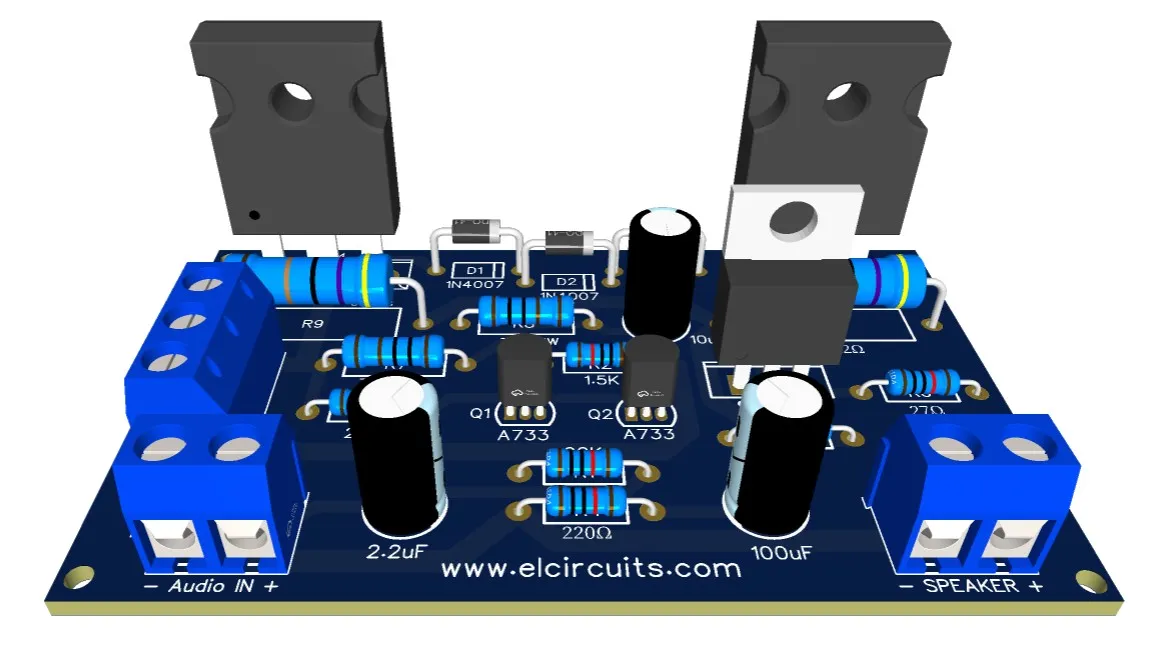

📂 The PCB and Project Files

To ensure your build is a success, I’ve put together a complete package with everything you need to replicate this project. The layout was designed following best practices to ensure signal integrity and make soldering the components easier.

📦 The package includes:

- Gerber files (For industrial manufacturing);

- PDF layout (For toner transfer method);

- Complete electronic schematic;

- Reference images and bill of materials.

(Secure download: .ZIP containing PDF, Gerber files and images)

💡 Fresh Ideas for Your Next Project

Did you enjoy this project? Then you'll love exploring other circuits we've prepared. Each one with its unique features and ideal applications!

- Build a 50W RMS Audio Amplifier with Mosfet | Complete DIY Guide

- 400W Class AB Amplifier using MJL4281A and MJL4302A transistors + PCB

- 200W RMS Power Amplifier With 2SC2500 AND 2SA1943 + PCB

- 300W RMS Power Amplifier - 2SC3858 and 2SA1494 Transistors + PCB

- 50W RMS Audio Amplifier with IRF530 and IRF9530 Mosfet + PCB

- 100W RMS Power Amplifier With 2 NPN 2SC5200 Transistors At Output + PCB

- Simple 3 Transistors Power Amplifier push a 600W RMS Subwoofer + PCB

🤔 Dúvidas Frequentes (FAQ)

To ensure your project is a success, we have compiled answers to the most common questions regarding this 100W amplifier circuit.

Can I replace the TIP142 and TIP147 with other transistors? 🔽

Yes, you can substitute them with other Darlington pairs, provided they have similar voltage and current ratings. Common equivalents include the 2N6284 (NPN) and 2N6286 (PNP). Always check the pinout (Base, Collector, Emitter) as it may differ from the TIP series.

Do I really need a heatsink for this amplifier? 🔽

Absolutely. The TIP142 and TIP147 dissipate significant heat, especially at high volumes. Without a proper heatsink (and thermal paste), they will reach thermal destruction in seconds. For 100W output, a large heatsink with thermal capacity of at least 1°C/W is recommended.

What is the difference between Class B and Class AB amplifiers? 🔽

Class B amplifiers use two transistors to handle each half of the waveform, which is efficient but can cause "crossover distortion." Class AB introduces a small bias voltage (like our diodes D1-D3) to keep the transistors slightly on, eliminating that distortion. This circuit operates effectively as Class AB due to that biasing.

Why does my amplifier produce a loud hum or buzzing noise? 🔽

Hum is usually caused by a "ground loop" or poor filtering in the power supply. Ensure your transformer's center tap (0V) is connected solidly to the PCB ground. Also, check that C2 and C3 are correctly installed. Keep input wires away from power wires to prevent electromagnetic interference.

🎓 Final Thoughts & Encouragement

Building a 100W amplifier is a milestone. It requires patience, attention to detail, and respect for safety. When you hear that first clear note playing through speakers you powered yourself, every bit of effort will be worth it.

Don't be afraid to experiment, but always measure twice and cut once. If you run into issues, check your soldering joints—cold joints are the enemy of reliability. Good luck with your build!

✨ Our Gratitude and Next Steps

We sincerely hope this guide has been useful and enriching for your projects! Thank you for dedicating your time to this content.

Your Feedback is Invaluable:

Have any questions, suggestions, or corrections? Feel free to share them in the comments below! Your contribution helps us refine this content for the entire ElCircuits community.

If you found this guide helpful, spread the knowledge!

🔗 Share This GuideBest regards, The ElCircuits Team ⚡

Português

Português Español

Español