This circuit built based on TEA2025 IC which is a monolithic integrated audio amplifier in a 16-pin plastic dual in line package manufactured by UTC.

The circuit has Internal Thermal Protector. It is designed for portable cassette players, mp3 players and radios.

You can also use it as your smartphone or PC audio amplifier. This circuit requires 9V power supply to work, you may use a power supply circuit with output 9V 500mA DC current or a 9V lead acid battery.

Features

- The power supply voltage range is from 3V to 15V.

- Working Voltage down to 3V

- Few External components

- Dual or Bridge Connection Modes

- High Channel isolation

- Very low switch On/Off Noise

- Voltage gain up to 45dB(Adjustable with external resistor)

- Soft clipping

- Internal Thermal protection

Working Explanation

Input Capacitor

Bootstrap

Power supply

Applications

- Electronic Instruments

- PC sound speaker

- Home theater systems

- Hi-fi electronic gadgets and devices

- Robotics applications

- Children’s gadgets and toys, etc.

|

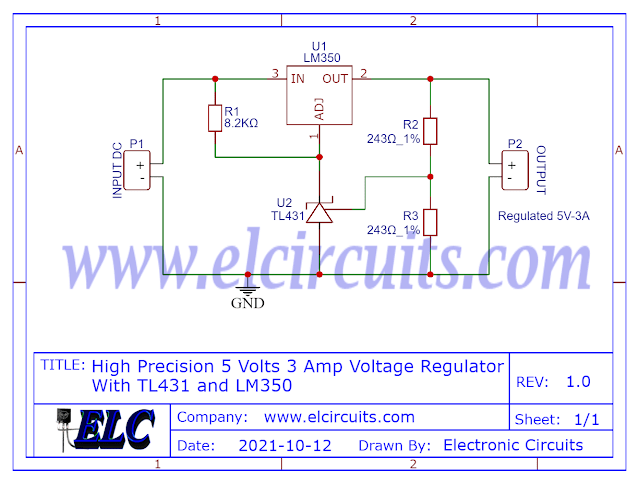

| Fig. 1 - Schematic 5W Stereo Audio Amplifier Circuit using TEA2025 IC |

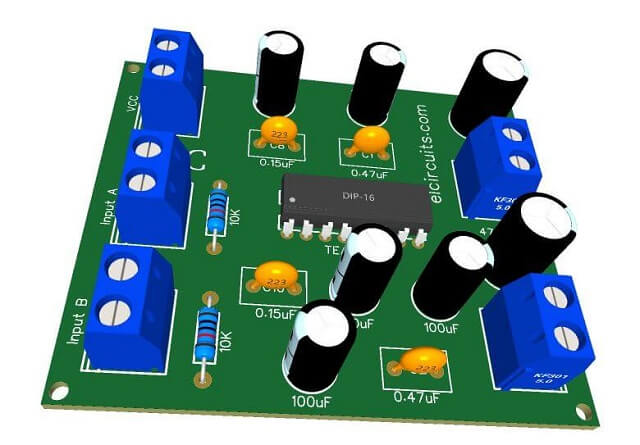

Components List

- U1 ................................ TEA2025 Integrated circuit

- R1, R2 ......................... 10K resistor (brown, black, orange, gold)

- C1, C2 ......................... 0.47uF ceramic, polyester capacitor

- C3, C4, C5, C6, C9 ..... 100uF electrolytic capacitor

- C7, C11 ....................... 470uF electrolytic capacitor

- C8, C10 ....................... 0.15uF ceramic, polyester capacitor

- P1, P2, P3, P4, P5 ....... Screw Terminal Type 5mm 2-Pin Connector

- Others ......................... PCB, tin, wires, etc.

PCB - Download

We provide the files with the PCB, the schematic, the PDF, GERBER and JPG, PNG and provide a direct link for free download and a direct link, "MEGA".

|

| Fig. 2 - 5W Stereo Audio Amplifier Circuit using TEA2025 |

Click on the direct link to download the files: Layout PCB, PDF, GERBER, JPG

If you have any questions, suggestions or corrections, please leave them in the comments, and we will answer them soon.

Subscribe to our blog!!! Click here - elcircuits.com!!!

My Best Regards!!!